Sewing Pattern Envelopes: How Packaging Supports Your Brand and Customer Experience

When selling physical sewing patterns, the envelope is more than simple packaging. Custom branded pattern envelopes play a key role in protecting the product, communicating brand identity, and shaping the customer’s first impression.

For professional pattern designers, a well-designed envelope supports both practical use and brand consistency. In this article, we look at how to choose the right branded pattern envelopes and how packaging decisions can add value without adding unnecessary complexity, alongside sewing pattern printing.

Why sewing pattern envelopes matter

Sewing pattern envelopes serve several important functions at once:

-

protecting pattern sheets and instruction booklets during handling and shipping,

-

presenting the product clearly at the point of sale,

-

reinforcing brand identity through design and print quality,

-

supporting repeat purchases through a consistent, recognisable look.

For customers, the envelope is often the first physical interaction with your brand. A clean, well-printed branded pattern envelope signals professionalism and care, while poor-quality packaging can undermine even the best-designed pattern.

Choosing the right type of sewing pattern envelope

The choice of envelope should match how your patterns are sold and distributed. Common options include:

Classic flat envelopes

A practical and cost-effective solution, suitable for both direct-to-customer sales and wholesale distribution.

Reinforced envelopes

Designed for heavier pattern sets or international shipping, offering added durability.

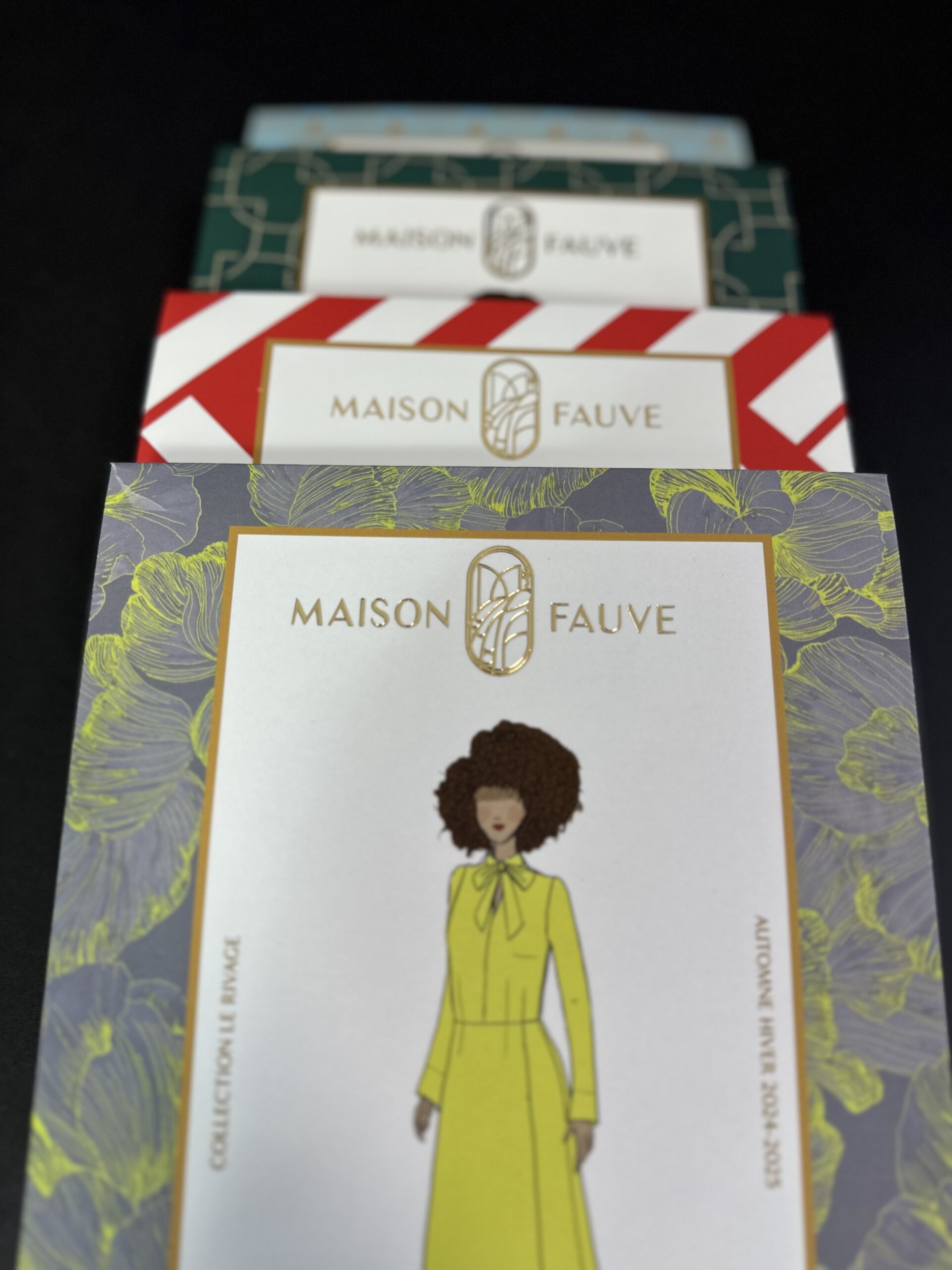

Branded envelopes

Custom pattern envelopes printed with your logo, pattern name, sizing information, and key visuals to ensure clear identification and strong shelf presence.

For designers offering multiple patterns, consistent custom pattern envelope formats make stock management and reprints much easier over time, especially when combined with pattern sets assembly.

Print finishes and details that add value

Sewing pattern envelopes do not need to be luxurious to be effective, but thoughtful finishing can elevate the product when used selectively. Options include:

-

high-quality paper stock with good opacity,

-

matte or satin finishes for a professional look,

-

clear, legible typography for technical information,

-

discreet use of embossing or foil stamping for special editions.

The key is balance. Finishing should support usability and brand positioning, not complicate production or increase costs unnecessarily within custom pattern envelope production.

Small runs, reprints, and limited editions

Many sewing pattern businesses operate with smaller print runs or frequent reprints. Digital printing makes it possible to:

-

produce short runs without excessive setup costs,

-

update envelope designs between releases,

-

create limited editions or seasonal releases,

-

test new products before scaling production.

This flexibility is particularly valuable for independent designers and growing brands producing custom pattern envelopes alongside sewing pattern printing services.

Sealing and assembly considerations

Envelope design should also account for how pattern sets are assembled and shipped. Envelope seals or branded stickers help prevent accidental opening and ensure the pattern arrives in good condition.

When custom pattern envelopes, pattern sheets, instruction booklets, and seals are designed as a complete system, pattern sets assembly becomes faster and more reliable, especially for larger orders and repeat production.

Working with a specialist sewing pattern printer

Choosing a specialist sewing pattern printer makes a significant difference. A specialist printer can advise on:

-

custom pattern envelope formats suited to folded or unfolded patterns,

-

paper choices that balance durability and cost,

-

finishes appropriate for repeat print runs,

-

packaging solutions that scale as your business grows.

This ensures that custom pattern envelopes are treated as an integral part of the final product, not an afterthought, and align with additional printing services where needed.

Summary

Well-designed custom pattern envelopes protect your patterns, support your brand, and improve the customer experience throughout the buying and unboxing process. By choosing appropriate materials, finishes, and production methods, designers can create packaging that is practical, consistent, and aligned with their brand values.

If you are planning to produce or update physical sewing patterns, working with a specialist printer can help you select custom pattern envelope solutions that support both your current needs and future growth.